Twinify

The SaaS digital platform that automates RFID tag assignment from inception, creating a secure Digital Twin of each textile in the cloud.

Twinify optimizes data assignment by keeping the EPC as a lightweight, universal identifier for the textiles while managing all related information in its cloud database – free from tag memory limits. This eliminates the need for re-encoding RFID tags requiring manual item handling and specialized equipment, reducing operational complexity and enabling instant, scalable data updates across the entire textile lifecycle.

Data Assignment Process

In textile manufacturing and commercial laundry operations, textile items such as towels, uniforms, or bed linen can have an RFID tag embedded in them, such as the Datamars LaundryChip™.

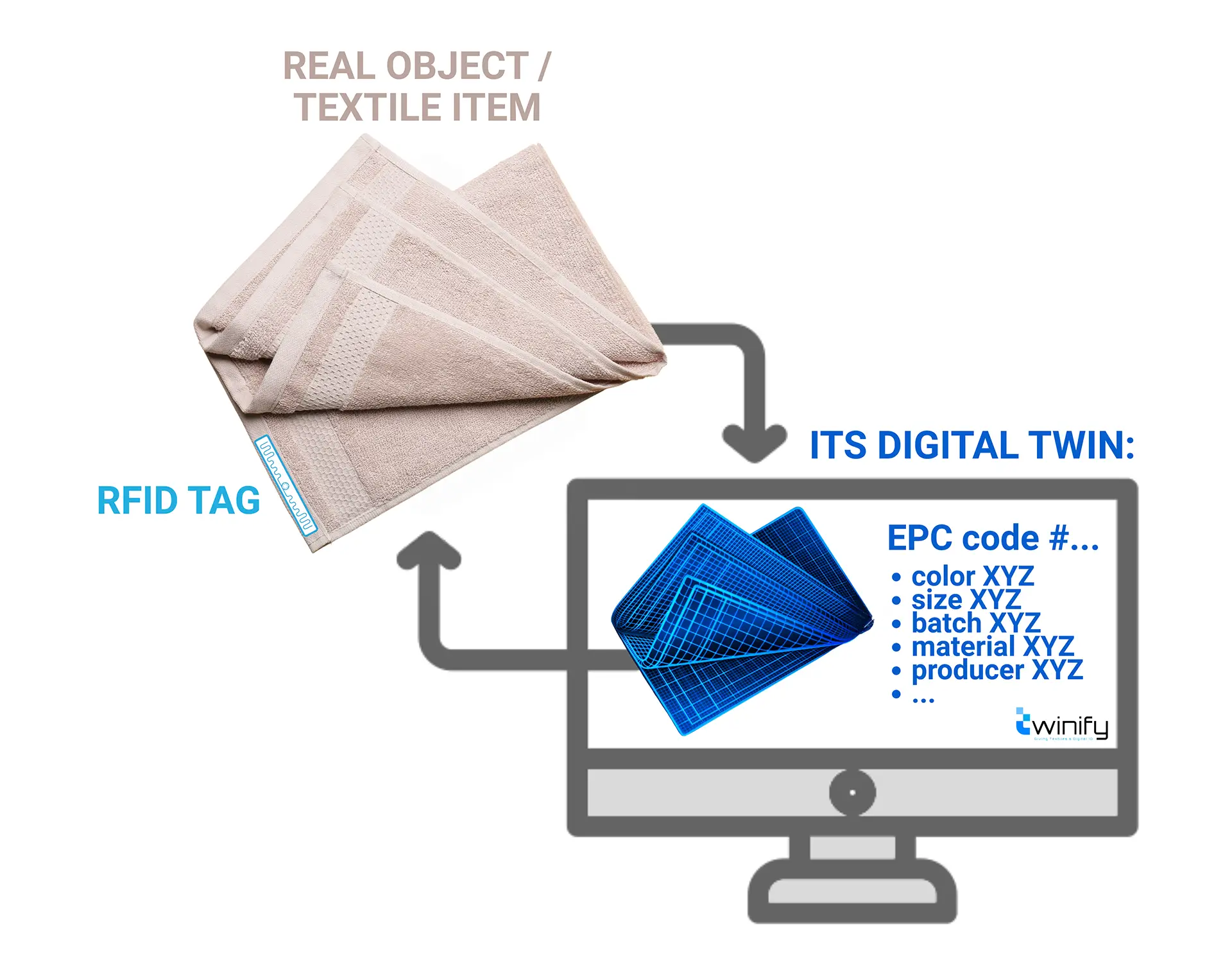

Each RFID tag carries a unique Electronic Product Code (EPC), typically represented as a 24-digit hexadecimal string. In Twinify, this EPC is captured during the assignment process using an RFID reader and stored in the platform’s cloud database, where it is linked to the specific textile item and its attributes—such as color, size, product type, article number, batch number, or customer-defined fields.

The Digital Twin

When an RFID tag is digitally assigned to product-specific data (e.g., customer, category, batch, color, size, order…), it creates a Digital Twin: a precise digital representation of the physical item stored in the cloud.

This Digital Twin follows the textile item throughout its whole lifecycle, from production to end-of-life.

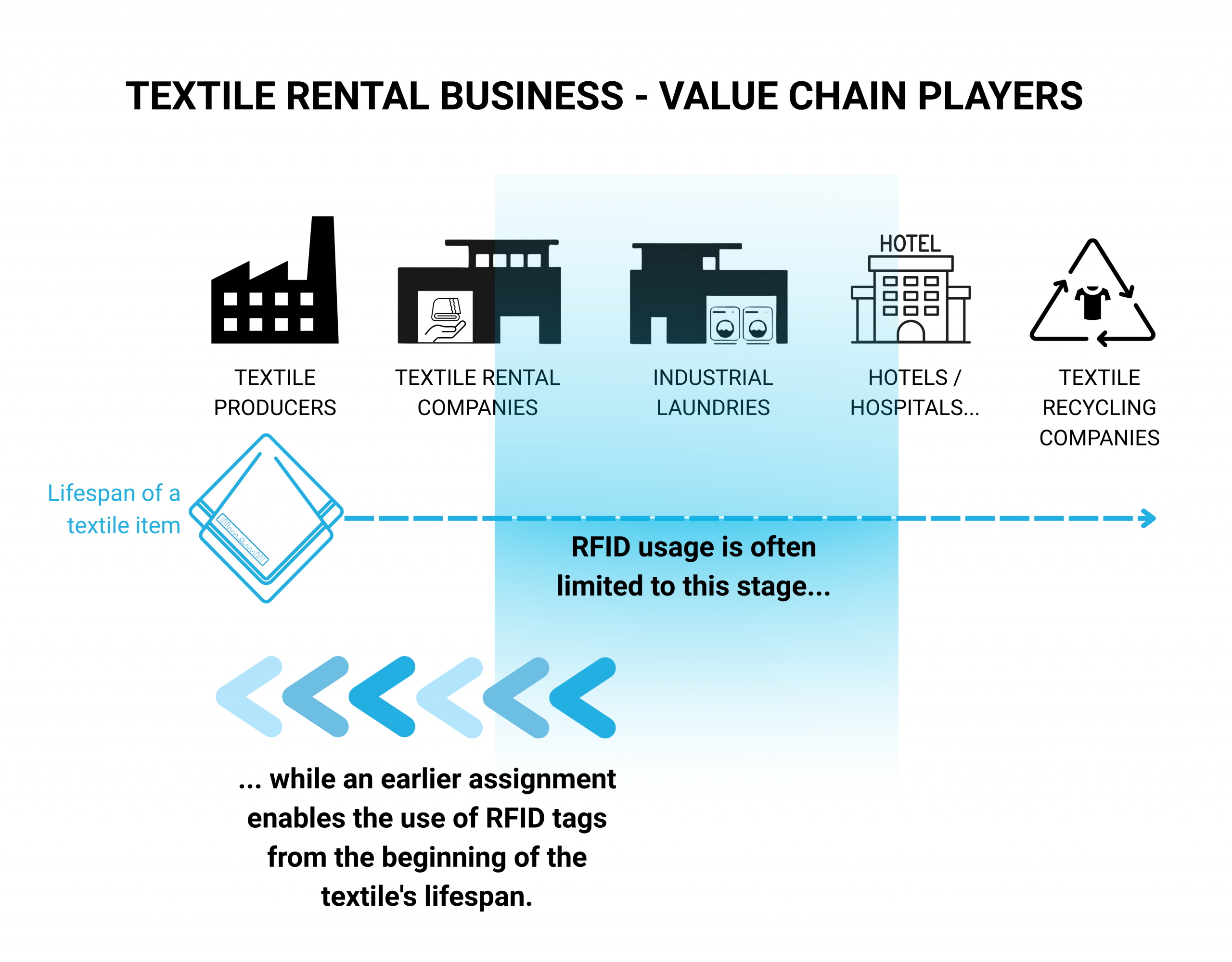

Gap in Textile RFID Use

RFID tags such as the Datamars LaundryChip™ are commonly embedded in or attached to textiles and garments at production sites worldwide, but data assignment is often delayed until the products reach the customer—typically the laundry.

This delay leads to missed opportunities, including:

- Cost-efficient data capture

- Digital Twin creation at the source

- End-to-end traceability across the supply chain

- Seamless data flows throughout the textile lifecycle

Datamars’ Solution: Twinify

Twinify is Datamars’ secure, cloud-based SaaS platform designed to streamline and optimize RFID tag assignment by creating structured Digital Twins for textile items. It transforms manual tracking into an automated, cloud-managed workflow with built-in validation, reporting, and seamless data integration. Acting as a central hub, Twinify connects to RFID readers, captures tag assignments, and ensures every tag is accurately linked to its digital record. The platform validates, monitors, exports, and manages all assignment data for RFID-tagged textiles.

Twinify’s defined workflows, validation checks, configurable user roles, and customizable data attributes make it adaptable to the needs of different organizations and operational setups.

The platform integrates with multiple RFID reader configurations—such as tabletop, tunnel, or cabin—giving organizations the flexibility to design an assignment process that fits their operations. With full software control, Twinify ensures consistency, accuracy, and efficiency across all setups.

All assignment data is stored in the cloud, where it can be viewed, searched, filtered, and exported in standard formats such as CSV. This makes Twinify the central hub for managing RFID-tagged textiles, enabling better visibility, streamlined workflows, and scalable operations.