The 1st LaundryChip specifically designed to identify mats

ELECTRICALLY TUNED TO RUBBER

Due to the significant difference in dielectric values between textile fibers and rubber, using a standard UHF laundry tag in a mat will result in suboptimal electrical performance, as it was specifically designed to function properly in the presence of textile fibers. This will significantly reduce the performances of the tag in both single read and bulk reading configurations. Upon contact with rubber, the MAT TAG delivers optimized reading results that are comparable to the highest performing UHF LaundryChips, making it appropriate for all UHF reading applications in a laundry environment.

PERFORMANCE COMPARISON:

When embedded in mats, reading through the rubber rather than the fabric, the MAT TAG reads up to 100% vs a classic textile tag only 67-77%.

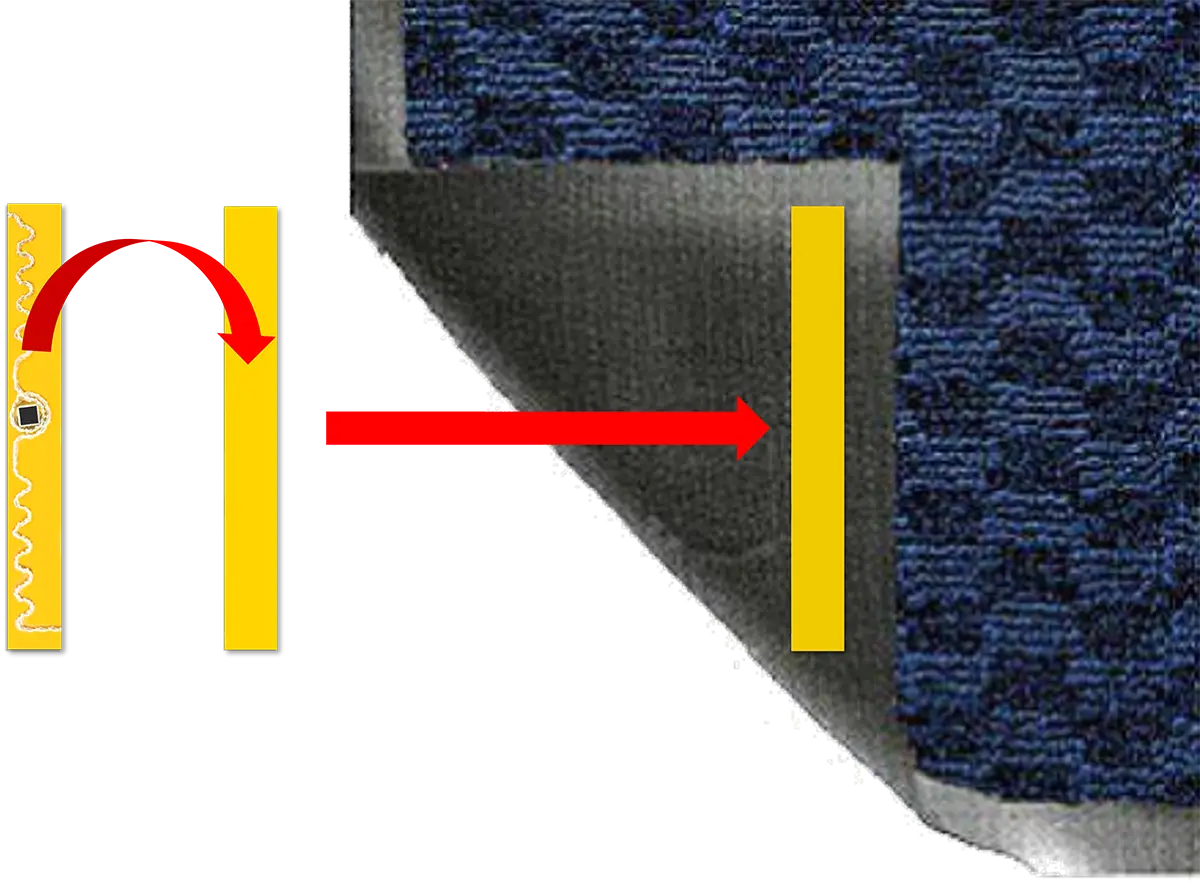

SIMPLY VULCANIZED DURING MANUFACTURING

The FT401 MAT seamlessly vulcanizes with the mat during production, ensuring it permanently fuses. Simply place the FT401 MAT at the mat’s bottom prior to vulcanization and it will completely fuse with the rubber mat.

- No preparation work required

- Zero application cost.

- Forever-stay: it can only be removed by cutting the mat.

HOW TO EMBED IT INTO MATS

Simply place the MAT TAG under the uncured rubber during the manufacturing process. Ensure that the transparent tag side, corresponding to the microchip side, is in direct contact with the mat rubber.

PERFECTLY BLENDED INTO THE MAT

- Totally imperceptible, it doesn’t add any unnecessary thickness to the mat

- No risk of “blister effect”:since the tag is not sandwiched between layers of rubber, there is no risk of delamination between tag and rubber that could weaken the mat’s mechanical strength.

CHIPPING COMPARISON: