The 1st UHF LaundryChiptm built to withstand Gamma Ray Sterilization

Why Gamma-Resistant RFID Matters in Healthcare

In hospitals, clinics, and medical cleanrooms, many textile items — including gowns, masks, and medical dressings — undergo sterilization processes such as Autoclave, Gamma ray, E-beam, or X-ray, depending on regional practices and specific application requirements.

in particular, Gamma ray sterilization exposes garments to radiation levels that irreversibly damage standard electronic components, making conventional UHF RFID tags unsuitable for sterilization workflows that rely on Gamma radiation.

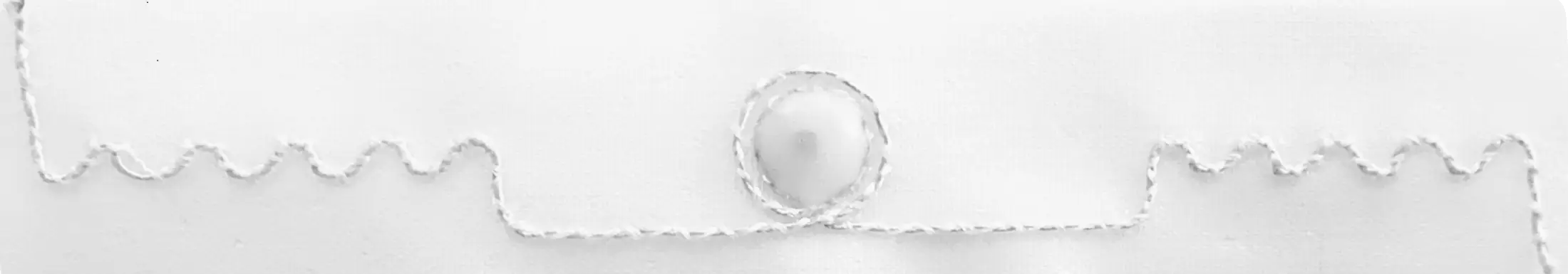

The Datamars FT501-GAM overcomes this limitation with a specialized semiconductor technology that ensures full immunity to Gamma radiation, making it the ideal solution for sterilization-critical applications.

Engineered with the same robustness as the rest of the Datamars UHF LaundryChip™ family, the FT501-GAM is designed to withstand the toughest industrial laundry conditions while remaining fully compatible with the existing LaundryChip portfolio.

Key Product Features

• Supports 100+ gamma sterilization cycles without degradation

• Designed for medical cleanrooms and sterile environments, including gowns, masks, and medical dressings

• State-of-the-art Datamars UHF performance, ensuring high read reliability

• Built on proven mechanical components from the industry-leading LaundryChip™ platform

• ISO 18000-6C compliant for maximum interoperability

• Oeko-Tex® certified materials for textile and healthcare compatibility

• Available in two versions: Source-taggable (sewn) and in Pouch

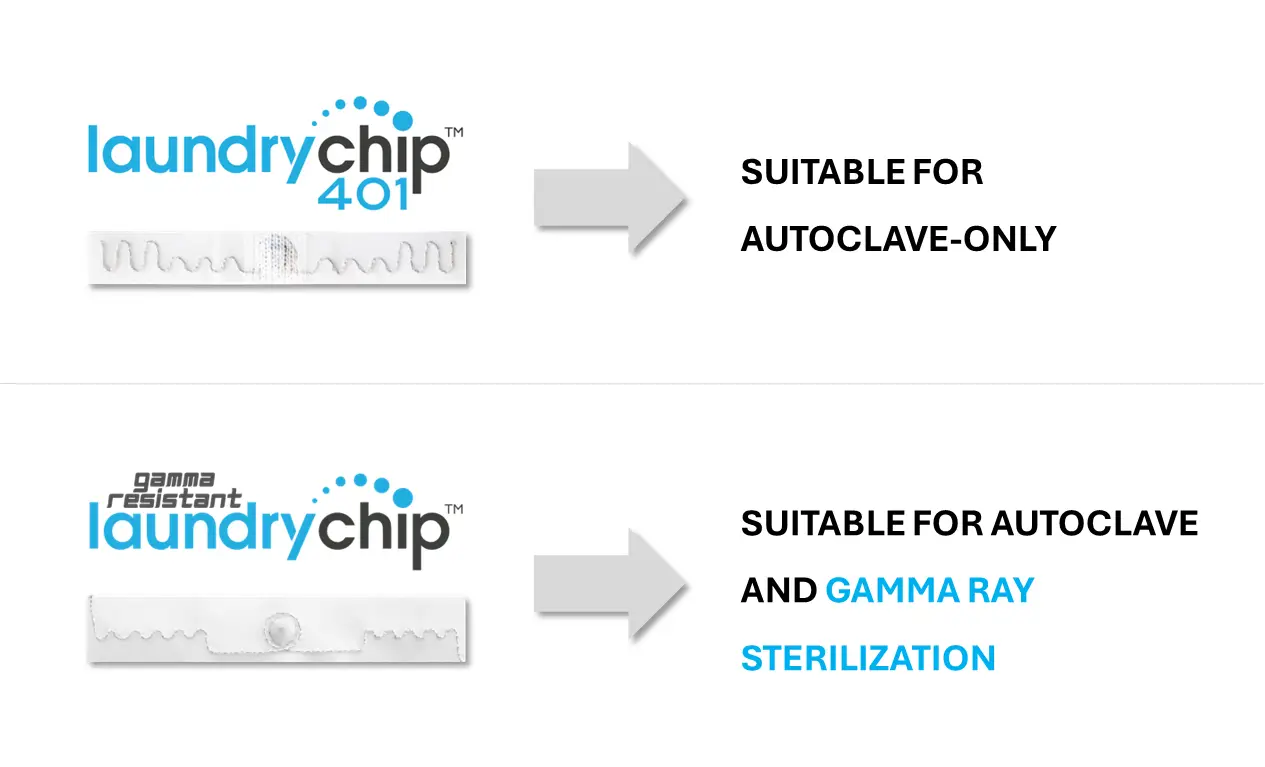

Which LaundryChip™ Fits Your Sterilization Workflow?

Different healthcare environments rely on different sterilization methods. Datamars offers dedicated LaundryChip™ options so you can match RFID traceability to your sterilization process.

| FT401 LaundryChip™ | Gamma Resistant LaundryChip™ FT501-GAM | |

|---|---|---|

| Primary sterilization method | Suitable for sterilization using Autoclave | Engineered for workflows using Gamma ray sterilization |

| Gamma ray exposure | Not suitable for Gamma ray sterilization, as radiation irreversibly damages standard electronic components | Equipped with specialized semiconductor technology designed to remain fully functional after repeated Gamma ray exposure |

| Typical healthcare use | Healthcare textiles processed with Autoclave-based sterilization, where Gamma is not part of the workflow | Healthcare textiles such as gowns, masks, and medical dressings processed with Gamma ray sterilization or where Gamma is part of the sterile supply chain |

| Mechanical robustness | Based on the proven Datamars UHF LaundryChip™ mechanical platform for demanding industrial laundry conditions | Relies on the same industry-proven mechanical components as the classic UHF LaundryChips™, designed for the toughest industrial laundry conditions |

| When to choose | Choose FT401 if your sterilization is Autoclave-only and RFID is not exposed to Gamma radiation | Choose FT501-GAM if your process includes Gamma ray sterilization and you need RFID traceability that remains reliable after irradiation |